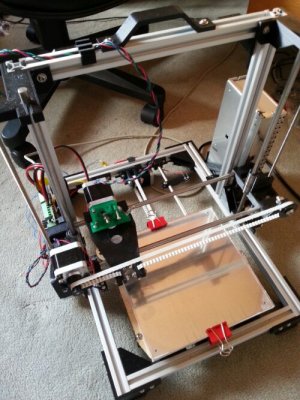

Originally one of the issues (for me) of running a 3D printer is that it has to be connected to a PC in order to print. Desktop machines tend to be power hungry and over powered for sending a simple ASCII sequence over serial. More modern firmware allows for SD cards to be used and the printer to print ‘stand alone’. However most still need a PC in order to start the print. Not to mention you have to take the SD card out of the printer, plug it into your PC, transfer the file, take it out of your PC, plug it into your printer before you can even start. That last bit has to happen even if you are using a LCD screen and controller on your printer.

Enter Repetier-Server. Although designed to work with nearly any computer (Windows, Mac, Linux, young or old) I think it is a great use of a low power RaspberryPi. The Pi doesn’t take much power in itself and sending ASCII commands over a serial connection isn’t processor intensive.

So what does R-Server offer over the more traditional SD card route? For me it enables easy access to the printer for sending files to print. Unlike using an SD card, R-Server has a web interface, meaning that any machine connected to the network can send a file to it. The current interface also adapts itself to the resolution it is displayed on, thus it works great on a tablet or phone. Another advantage is that while the printer is working, you can add more files to the queue. You still have manual control too, being able to move the printer as well as set temperatures etc. It also opens up the printer for more than one user, so for a work environment where several people need access, this facilitates an easier way to share the machine.

When uploading files you have two options, either upload as a one off job or store in a rudimentary models database. If uploaded as a one off, the file is deleted in completion of the print, if you want to print again you will need to re-upload. Completion means that the print actually finished or if you click the stop button. It is annoying that the stop button also removes the file because I have had to stop prints before because they didn’t stick to the bed and I needed to restart. As R-Server deletes the file I had to re-upload it. Not an arduous task but inconvenient.

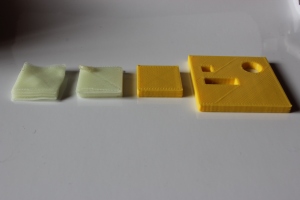

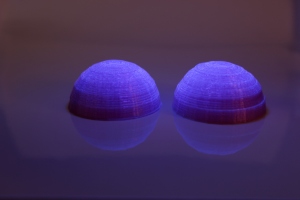

The model ‘database’ is a great way of storing items that you may print over and over. If you are running a company printing out repetitive parts – say a printer – then you can hold all the plates that need printing and copy to the job queue when needed. At the moment the model database is a single directory so everything is listed in one line. If you are making several different types of printer then this could be an issue finding the right model. I have brought this up with the developer and hopefully the next version will have directories.

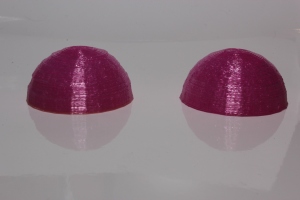

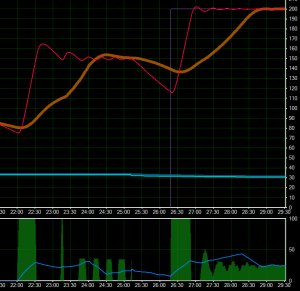

Another talent of R-Server is that it can control more than one printer. Each machine takes up about 5MB of RAM while printing, so in theory you could have 50 machines hanging off of one 256MB RPi! Whether the processor could deal with that I am not sure though. I have had my two printers running simultaneously and it had no issues.

Overall using Repetier-Server has simplified my workflow and use of my printer. Not only does it mean that I no longer need to have my desktop machine running while printing, I can transfer files simply (and while the printer is working) and monitor its progress on any networked machine.